Screen Printing Custom T-shirts Abilene Can Be Fun For Anyone

Wiki Article

The Buzz on Screen Printing Custom T-shirts Abilene

Table of Contents9 Easy Facts About Screen Printing Custom T-shirts Abilene ShownThe Best Strategy To Use For Screen Printing Custom T-shirts AbileneExcitement About Screen Printing Custom T-shirts AbileneGet This Report on Screen Printing Custom T-shirts AbileneGetting The Screen Printing Custom T-shirts Abilene To WorkNot known Facts About Screen Printing Custom T-shirts Abilene

No blending required, treatments exceptionally quickly, pricey, suitable for thorough job. Combination of Diazo and SBQ, requires blending, overall remedy time is less than Diazo, price is less than SBQ. The clear acetate movie is put on the emulsion-coated mesh display very carefully under a bright light which causes the emulsion to set and develop.Subjecting the screen for a details time will harden the uncovered locations of the screen, and the remaining unhardened emulsion, if any kind of, will be washed away to leave a clear imprint on the display. The screen is then dried, and if there are any touch-ups called for, it will be done by the printer to make the imprint as near the original design as feasible.

The product to be published is positioned level on the printing board, and the screen in addition to the material in the preferred position, ready to be published. In this action, the published design will come to life. The screen is lowered down to the printing board. The desired colour ink is included in the top of the display.

The ink presses through the open areas of the pattern and transfers on the underlying silk, consequently printing the layout on the product. The stencil will have served its purpose once all the products are published. An unique washing fluid is made use of to get rid of the emulsion to recycle the mesh for producing brand-new stencils.

The Only Guide for Screen Printing Custom T-shirts Abilene

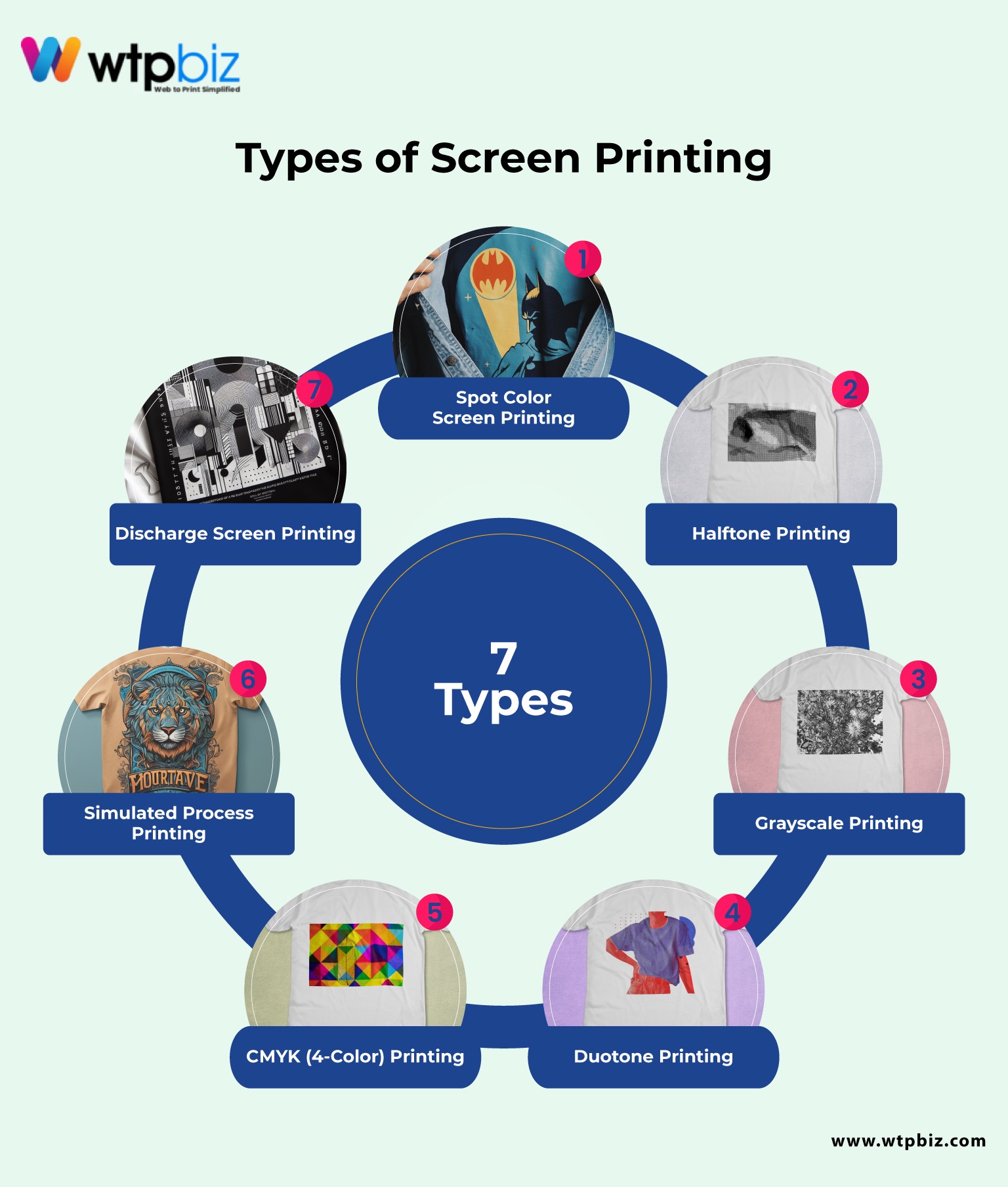

There are six various types of screen printing procedures. The most common display printing strategy is place colour screen printing.It is much easier to use as contrasted to other screen printing techniques. It can be an excellent choice for printing on t-shirts, coats, and hoodies.

In enhancement, it is a cost-effective method because only one colour of ink is used. Grayscale printing is an excellent method of printing full-colour photos as one colour grayscales or halftones. The print will look extra comprehensive if the halftone has even more dots. It is not a black and white method; rather, it takes out the CMY or RGB or colour scales only however in shades of grey.

Getting My Screen Printing Custom T-shirts Abilene To Work

Duotone printing makes use of the combination of two halftones for printing the same picture with 2 colours. A black halftone is printed with black ink, and then a 2nd halftone is printed with colour ink. This technique resembles sepia-toned print in digital photography. It provides an innovative and artistic effect.

The substitute printing procedure integrates the four-colour printing procedure with place colour printing. Because this strategy is helpful for both lighter and darker shades, it is flexible and popular with people looking to produce photorealistic print information.

Some of these advantages include: One of the main advantages of screen printing is its versatility. It can be utilized on any type of type of material, plastic, timber, glass or even steel. And also, multiple colours can be utilized. There is almost unlimited design flexibility when utilizing screen printing. Contrasted to other printing techniques, display printing can use a hefty ink protection, causing a sturdy design.

Screen Printing Custom T-shirts Abilene - Questions

Screen printing is just one of one of the most efficient and fast printing techniques once a screen has been developed. It is a superb option if the very same style is to be published over and over once more (Screen Printing Custom T-Shirts Abilene). The display printing process is rather simple, whether it is automated or done by hand. Furthermore, the called for tools are likewise not difficult or costly to replace.

Personalized screen printing is a process that uses a mesh display to push ink in a predetermined design onto the material of your choice. Screen printing is popular for personalized tee shirts, sweatshirts, jackets, and extra. Custom screen printed t-shirts or other screen-printed garments are the best method for businesses to improve their brand name visibility.

Things about Screen Printing Custom T-shirts Abilene

The ink's durability guarantees that prints stand up to repeated washing and wear, making it excellent for textiles like t-shirts, hoodies, and shoulder bag. This method deals with a vast array of surface areas, including textiles, plastics, glass, wood, and metals. Its versatility enables organizations and makers to use styles to items like clothing, marketing items, signage, and product packaging.

Innovations like computer-to-screen (CTS) and direct-to-screen (DTS) innovations are changing the display printing process. These approaches eliminate the requirement for conventional film positives by digitally transferring screen printing styles directly onto the screen.

The smart Trick of Screen Printing Custom T-shirts Abilene That Nobody is Discussing

While rooted in tradition, display printing has welcomed technical developments to fulfill contemporary needs. Its combination of craftsmanship and development ensures it continues to be a top selection for imaginative and industrial printing projects. Screen printing proceeds to be a trusted and versatile printing method, offering vibrant shades and resilient designs that attract attention on a range of products.

For garment design that requires a high level of vibrancy when printing on dark premises, display printing is still the ideal alternative.

Therefore higher volumes can be mass created using display printing extra promptly and more expense efficiently for bigger website orders. Screen printing accommodates a vast range of materials, consisting of plastic, textile, rigid plastic, foam board, steel, glass and several others.

Report this wiki page